Impact Mill

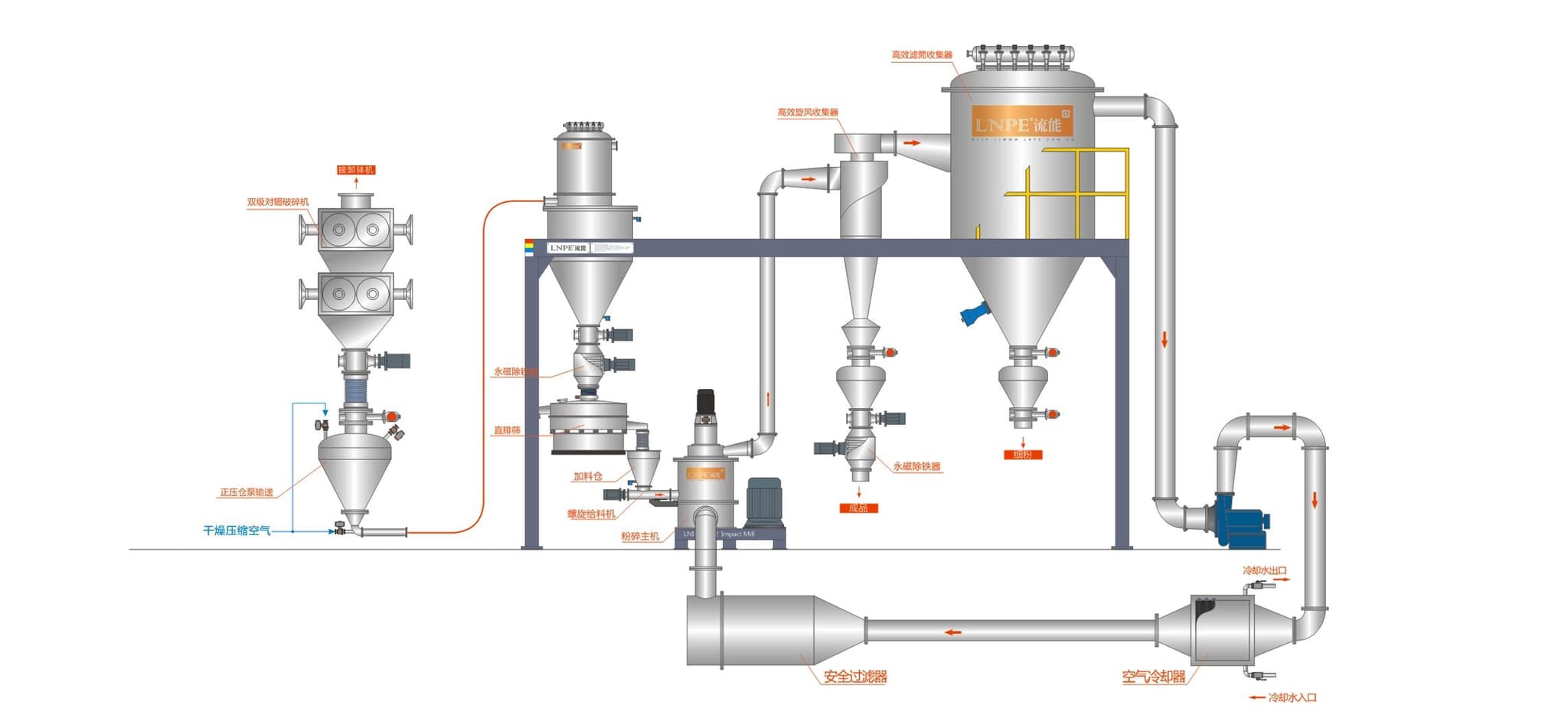

The LNPE Impact Mill combines two size-reduction mechanisms—high-speed hammer impact and hammer-to-liner compression—to achieve ultrafine grinding in a single continuous process. After comminution, material enters the built-in turbine classifier: particles that meet the target size are discharged as product, while oversize fractions are automatically recirculated for further milling.

Engineered for a wide spectrum of feed characteristics (adhesive, fibrous, heat-sensitive, etc.), the LNI system optimizes rotor hammers, toothed stator rings, and classifier geometry within a precisely controlled airflow. The result is high grinding efficiency, low specific energy consumption, and consistently narrow particle-size distributions—all in a compact, production-ready package.

Feature:

- High-capacity throughput with exceptionally low specific energy consumption

- Optional full-ceramic process lining to virtually eliminate ferromagnetic contamination

7×24 Standby Professionally

Pre Sales Consultation

Professional purchasing consultation

Scheme Customization

Tailor-made design solutions

Product Selection

Reasonable Product Configuration

Product Selection

Processing solution consulting service