Jet Pulverizer

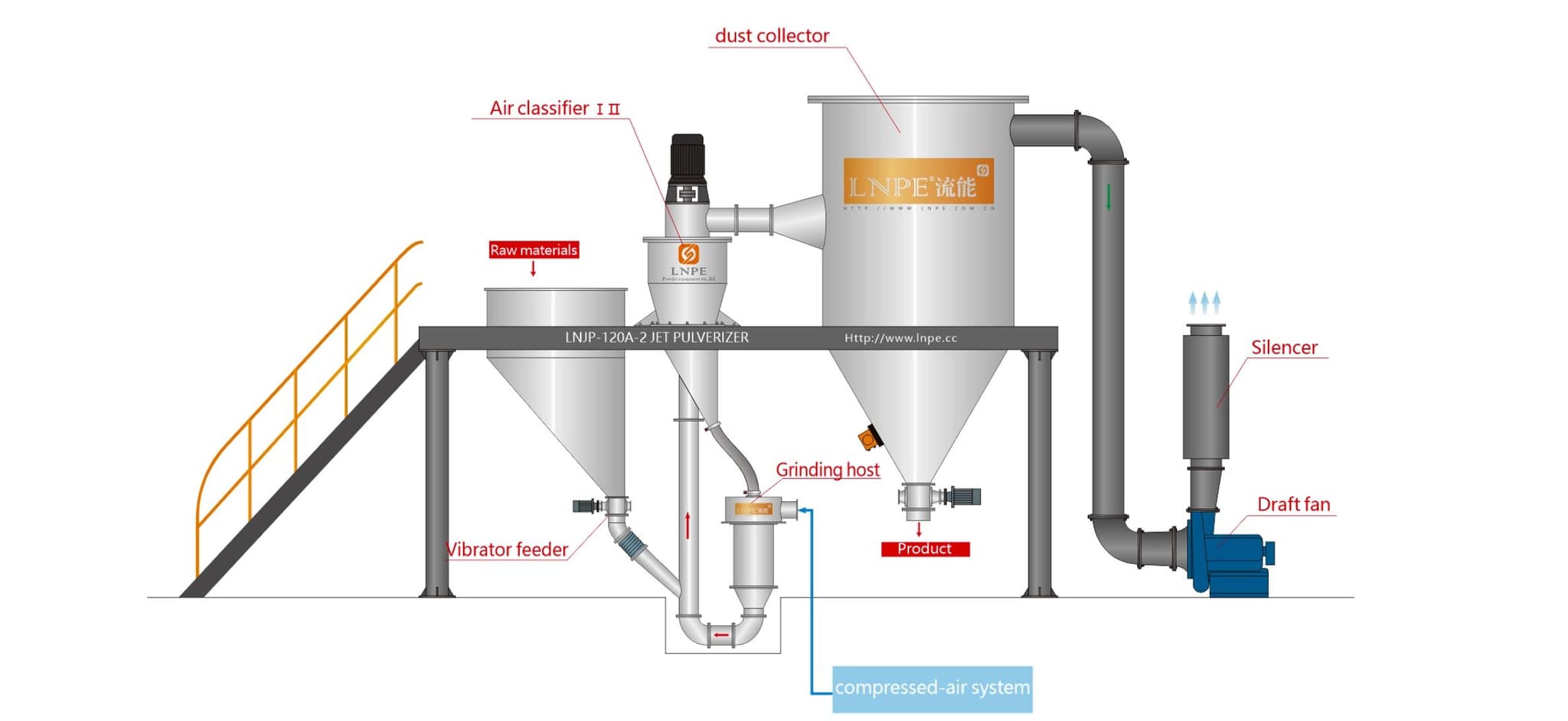

Working Principle

The Jet Pulverizer is a patented, next-generation grinding-and-classification system designed for processes that demand narrow particle-size distributions at high throughput with minimal energy draw.

Immediate Classification – As feed stock enters the unit, an integrated high-precision turbine classifier instantly removes material already within specification.

Single-Collision Milling – Oversized particles are channeled into the jet-milling chamber, where supersonic nozzles generate a single, high-energy impact.

Ultra-Short Residence Time – After impact, the material is routed back to the classifier. In-spec particles exit the system; only coarse material recirculates. Because each particle remains in the milling zone for mere milliseconds, secondary grinding is virtually eliminated, yields are maximized, and the generation of unwanted ultrafines is greatly reduced.

The result is stable, repeatable particle sizes, exceptionally high yields, and industry-leading energy efficiency.

Key Application Areas

- Sintered ternary cathode powders

- De-agglomeration and micronization of sintered silicon–carbon (Si-C) composites

- De-agglomeration and dispersion of coated graphite anode materials

- Reflective and high-purity silicon powders

- Precision milling of lithium-ion battery cathode and anode constituents

Engineered for demanding advanced-materials manufacturing, the Jet Pulverizer delivers consistent performance across the entire battery-materials value chain and other high-value powder markets.

Feature:

- Controlled grinding, high yield, stable particle size, low energy consumption, and large output

- The milling strength is easy to control, high yield, low fine powder content

- Minimal impact on particle surface morphology, with little damage to the shape of particles

7×24 Standby Professionally

Pre Sales Consultation

Professional purchasing consultation

Scheme Customization

Tailor-made design solutions

Product Selection

Reasonable Product Configuration

Product Selection

Processing solution consulting service