Jet Mill

Working Principle

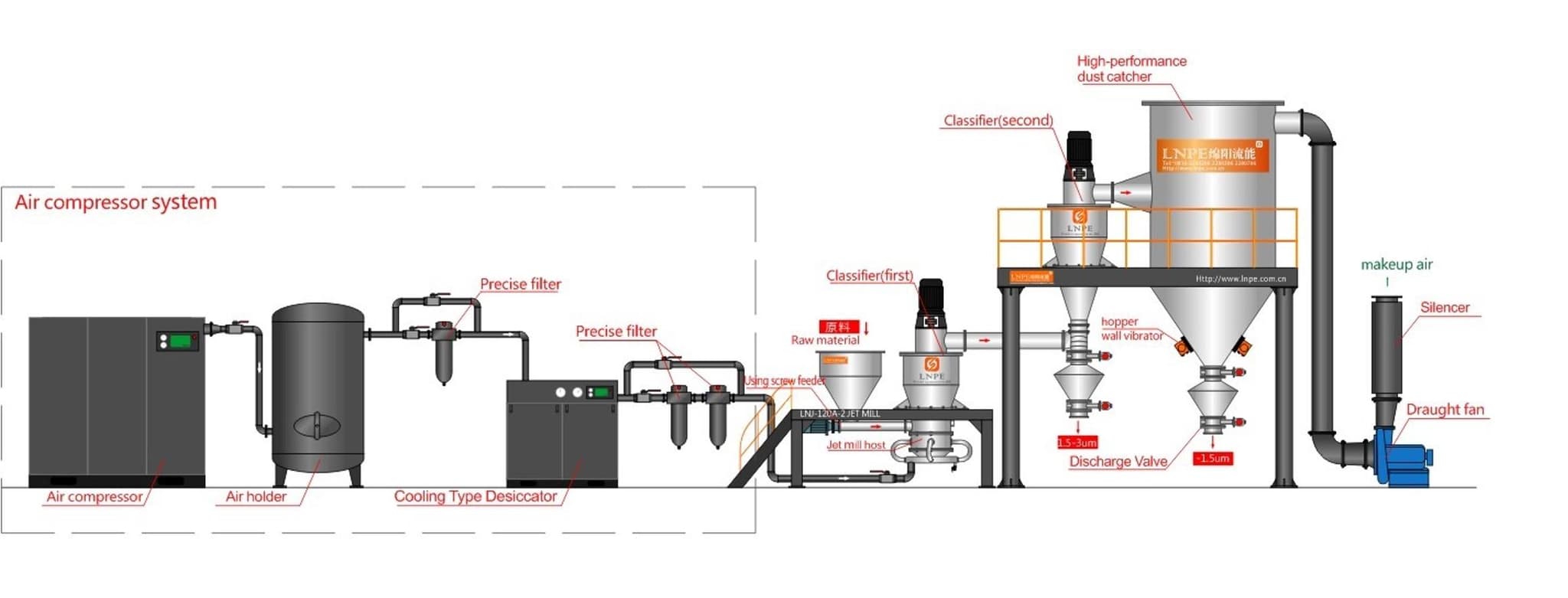

The LNJ Jet Mill utilizes multiple nozzles to generate high-velocity, sonic-speed airflow, enabling ultrafine pulverization of materials through particle-on-particle collisions. The finely ground particles are then carried into a high-efficiency turbine classifier, where oversized particles are separated and returned to the grinding chamber for further processing.

Engineered based on theoretical modeling and advanced numerical simulations, and integrating both domestic and international technologies, the LNJ Jet Mill represents a new generation of precision grinding equipment.

Its optimized structural and aerodynamic design significantly enhances the efficiency of both the high-speed airflow and the classifier. The system offers numerous advantages, including low energy consumption, minimal over-grinding, a narrow particle size distribution, and user-friendly operation.

LNPE offers a versatile range of solutions tailored to specific material characteristics, including low-temperature jet mills, high-temperature variants, and inert gas-protected closed-loop systems—ensuring safe, efficient, and precise performance across a wide range of industrial applications.

Feature:

- Low energy consumption

- Materials collision each other without contamination, effective for Mohs 1-10 hard Material

- Fully automatic control, easy to operate

- Omniseal negative pressure operation, no contamination.

7×24 Standby Professionally

Pre Sales Consultation

Professional purchasing consultation

Scheme Customization

Tailor-made design solutions

Product Selection

Reasonable Product Configuration

Product Selection

Processing solution consulting service