Shaping Mill

Working Principle:

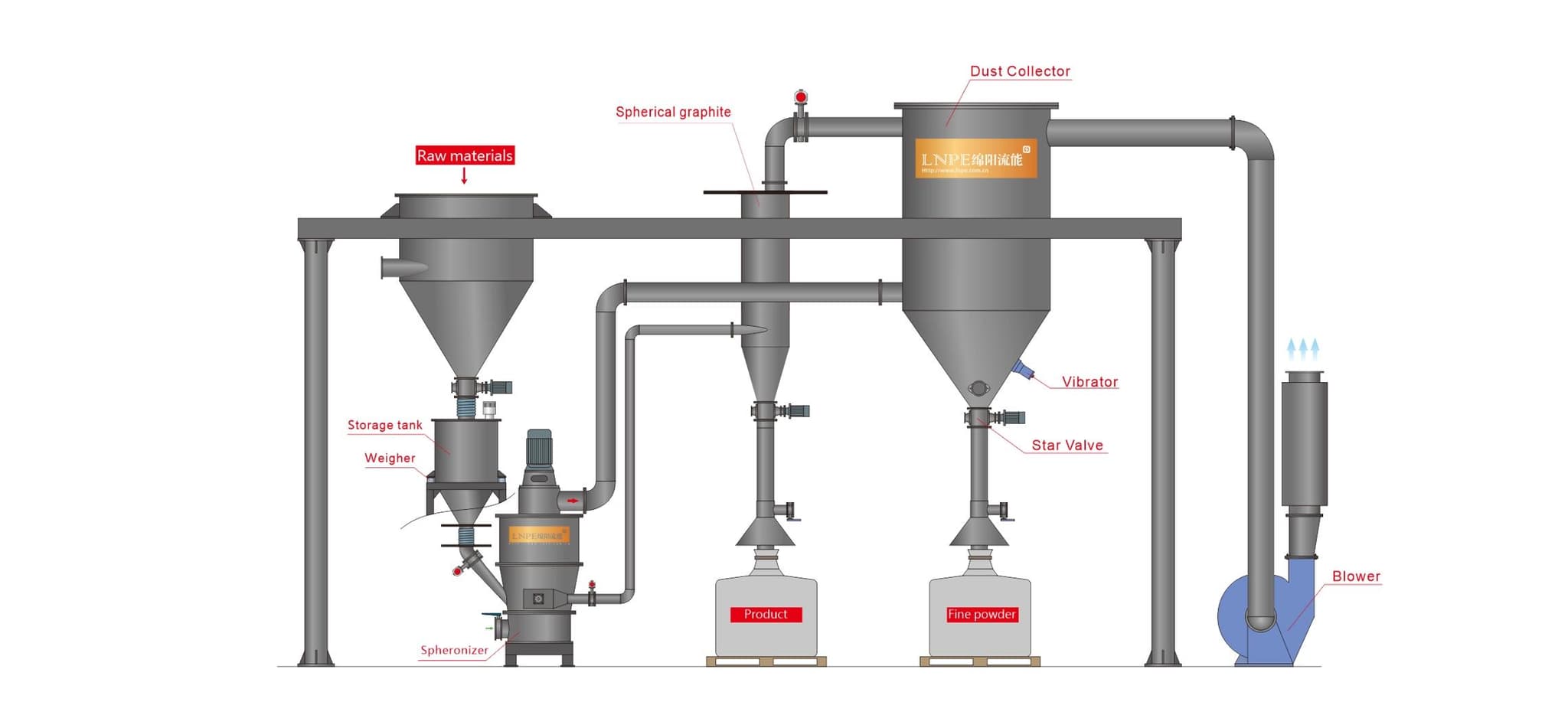

The LNPE Shaping Mill employs a high-speed rotor–stator assembly inside a precisely engineered airflow field. Feed powder is accelerated into the shaping zone, where controlled particle–particle and particle–wall collisions round sharp edges, smooth surfaces, or accentuate aspect ratios as required.

A built-in dynamic classifier continuously extracts in-spec particles; oversize or under-shaped fractions are recirculated for additional passes. By tuning rotor speed, airflow, and classifier cut-point, the system delivers narrowly distributed particles in the target morphology—whether near-perfect spheres for flowability, platelets for reinforcement, or elongated grains for specialised functional properties.

Typical Applications:

- Spheroidisation of natural and synthetic graphite for lithium-ion battery anodes

- Surface smoothing of mica and talc to improve dispersibility in polymers and coatings

- Aspect-ratio enhancement of wollastonite and glass fibres for mechanical-strength additives

- Custom shaping of ceramic, metal, or specialty-mineral powders where downstream performance hinges on precise particle geometry

Feature:

- Morphology on demand – spheroidal, prismatic, or high-aspect shapes

- One-pass shaping + sizing

- Modular rotor for diverse powders

- High yield, near-zero contamination

- Low energy, minimal OPEX

7×24 Standby Professionally

Pre Sales Consultation

Professional purchasing consultation

Scheme Customization

Tailor-made design solutions

Product Selection

Reasonable Product Configuration

Product Selection

Processing solution consulting service