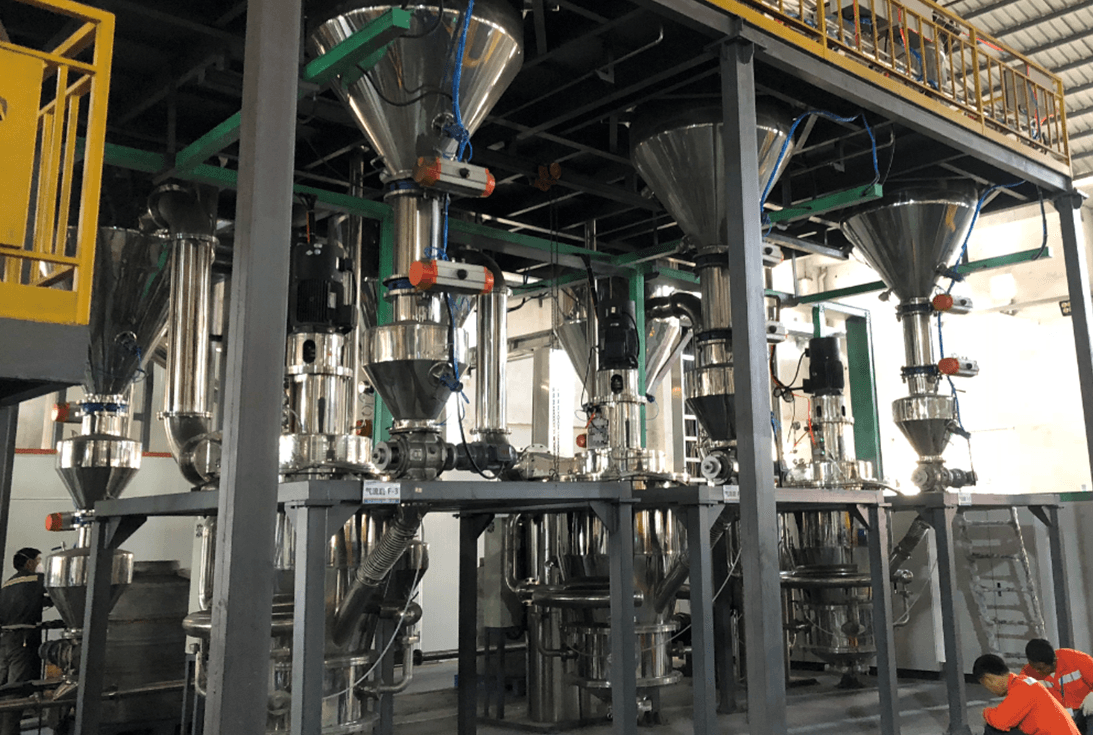

Shaping Mill Project

The Shaping Mill tailors particle morphology—spheroidal, multi-faceted, or high-aspect—while simultaneously trimming size to sub-micron levels. Its all-ceramic, metal-free lining preserves purity and the low-temperature process protects heat-sensitive powders. Ideal for: graphite spheroidisation, mica plate-edge rounding, wollastonite aspect-ratio enhancement, and other specialty fillers where shape directly drives performance.